Manufacturing Engineer

2026

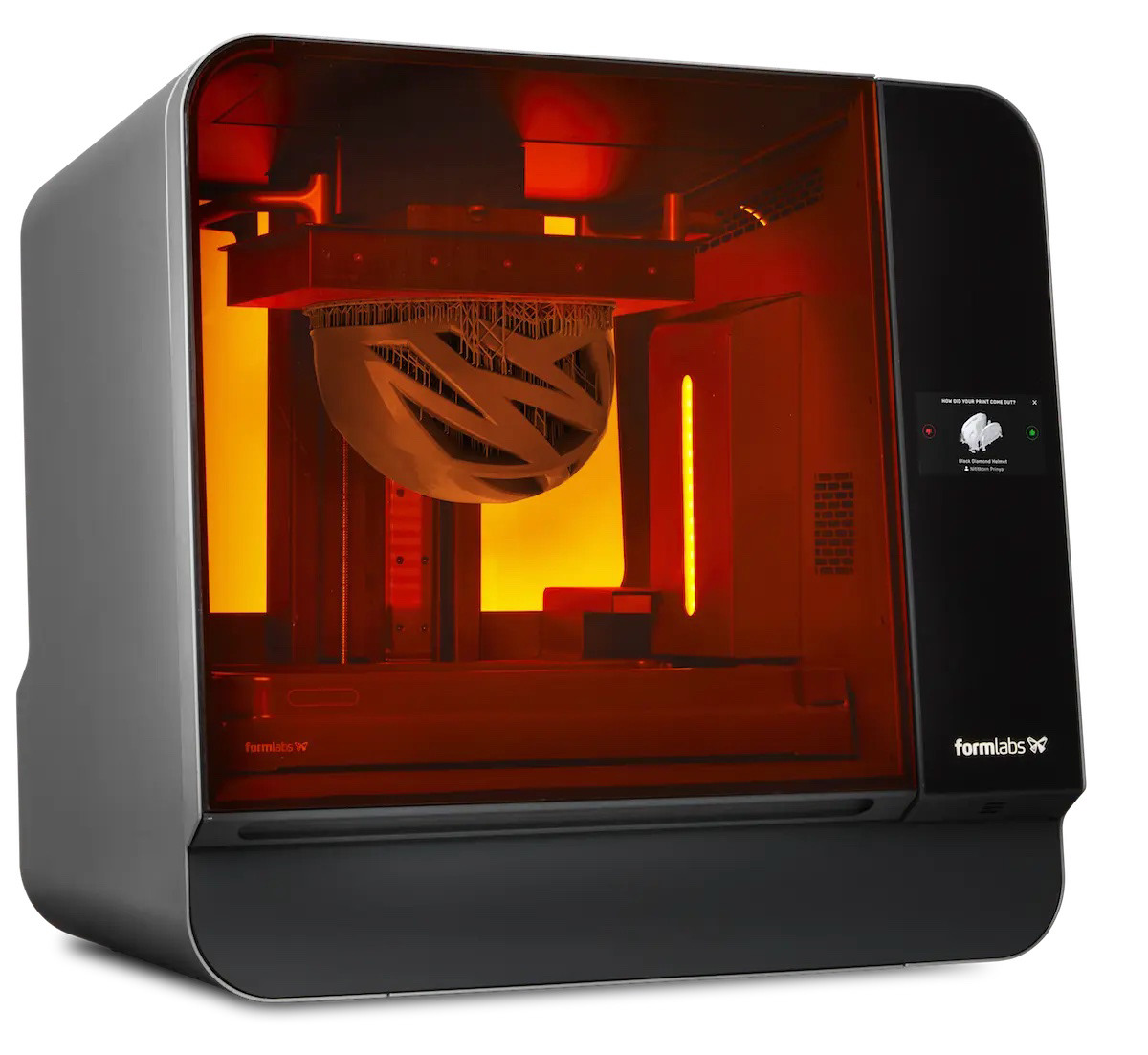

- Leading manufacturing development of a next generation 3D printer

2025

Mexico Aligner Production Project

- Recommended by the COO for a temporary role rotation to lead end-to-end implementation of a high volume dental aligner production workflow using Form 4L printers along with specially developed software and material solutions at a Mexico based production facility

- Debugged three critical technical issues during onsite pilot (CPU thrashing, file overwrite, print adherence)

- Coordinated multidisciplinary work to make customer specific modifications (print settings changes, material modifications) while decreasing print time, improving part accuracy, and increasing packing density

Other Projects

- Developed a structured template for NPI readiness by each product development phase. Adopted by each of four new generation NPI programs

- Improved F4L BP Flex yields from ~70% to >99% through CNC DFM review machining control lots

2024

- Owned the product realization of the Form 4L backlight module

- Reduced LCD potting proudness failure rate from 18% to 2%, saving $300k annually using detailed data analysis to drive process improvements to the gluing process for Texture-Laminated LCD <> Carrier Frame bonding

- Sourced and implemented automation solution to increase the resin cartridge RFID programming process by 50%

- Brought Form 4 and Form 4L BLU and LCD lines into stable mass production and implemented cost downs totaling more than 500k in annual savings

2023

- Owned the product realization of the Form 4 backlight module

- Managed schedule and technical readiness from quote packet creation through pre-production builds to MP ramp for backlight module

- Designed, built, and tested three fixtures for in-line and end of line optical testing

- Pushed for design convergence to the operations schedule while anticipating and reacting to design changes

- Championed burn-in and reliability testing requirements cross functionally with EE and data science

- Collaborated with the sustaining engineering team to investigate and review data to respond to early lifetime failures on galvos

- Communicated progress to engineering leadership, managed manufacturing risks, collaborated across disciplines (EE, MechE, optics) to troubleshoot functional issues

- F3L tank V3 87% to 91% print success while increasing yields from 90% to >99%

- Supported second sourcing and Vietnam mold transition cost downs for F3 resin tanks

2022

- Owned the sustained production of eight product lines produced by a CM building 20 million dollars of annual production in collaboration with a MFG program manager and two APAC engineers

- Managed an intern and advised on her projects for internal change tracking dashboard, measurement jig development & verification, and test fixture duplication & validation

- Created a live updating commodities usage tracking dashboard to allow demand planning team to improve forecasting tier two supplier optics demand based on current usage rates

- Initiated a process to consistently reporting of ECO implementation across our two primary CMs

- Spearheaded a F3L tank yield improvement project resulting in 700k in annual scrap cost savings

- Supported initial operational tasks for next generation optical modules including RFQ packet creation, manufacturable risk identification and assessment of technical capabilities of potential CMs

EOY promotion to Manufacturing Engineer II

2021

- Provided manufacturing support for all of our tank products and their direct relationship to print success metrics by maintaining close ties with our SLA mechanical engineers

- Redefined quality and traceability standards for our PMP film to prevent future shortages

- Establishing JIRA project communication with a contract manufacturing for issue tracking

- Guided the Wash and Cure L products through technical issues (heater fan issues, WiFi failure WIP build up, gaps and flushness, MP ramp dashboarding, turntable gears) from PVT through MP ramp and to zero backlog

- Built and tested jigs to support ongoing laser module production

Products

Form 4 Backlight Unit

Responsible for bringing the BLU from prototype to mass production

Wash L

Cure L

Form 3L

Form 3L Tank

Form 3 Tank

Managed NPI of Wash L and Cure L from PVT to Zero Backlog

Supported the transition of Form 3L from initial ramp to sustained production

Responsible for manufacturing improvements on Form 3 and Form 3L resin tanks including Vietnam transition of Form 3 tanks and launching a new version of the 3L tank to improve yield and increase print success rates

Internship Projects